Did You Know?

Engine bearings are made of layers of different metals, with some layers even thinner than one-thousandth of an inch.

An engine has several moving parts connected to one another, such as rods and pistons. To prevent the connected parts from wearing each other out, they need to be lubricated. This lubrication is provided by inserting bearings between surfaces, which rub against each other. Such bearings can be either of a split-sleeve or anti-friction type.

Split-sleeve bearings are a circular shell made of two halves which fit into each other. Lubrication is provided by a thin layer of oil between the bearing and the part it is fixed on. An anti-friction, or ball bearing, uses moving components like balls to reduce friction. However, most bearings used in IC engines are of the split-sleeve type, because the small contact area in ball bearings cannot handle the heavy stresses produced in such cases. The three main types of engine bearings are connecting rod (or rod), crankshaft (or main), and camshaft bearings. The definitions of rod and main bearings, along with the differences between them are given in the following sections.

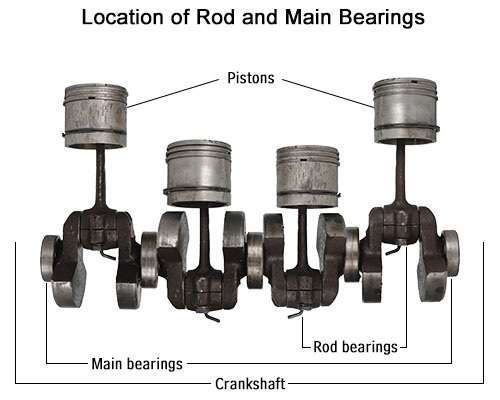

Location

In an IC engine, the pistons are attached to connecting rods, which in turn are attached to the crankshaft. Finally, the crankshaft is attached to the engine block. Rod bearings are inserted between the rod and the crankshaft. Main bearings are present between the crankshaft and the block.

Purpose

The gas-air mixture in each cylinder of an engine explodes and pushes the pistons downwards. The up-down motion of each piston is converted into rotation of the crankshaft by connecting rods. However, the connecting rod is under tremendous strain, because it is connected to two parts which move in different directions. Therefore, rod bearings are inserted where the rod comes into contact with the crankshaft. These rod bearings help the connecting rods rotate the crankshaft without breaking under pressure. The crankshaft is placed in grooves called saddles inside the engine block. Ordinarily, the power produced by all the connecting rods may disturb the position of the shaft, rather than rotate it. To prevent this, main bearings are inserted between the crankshaft and the saddles of the engine block, so that the shaft (moving part) can rotate freely inside the block (stationary part).

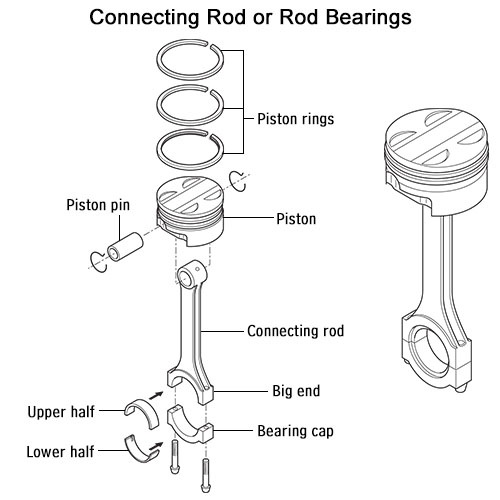

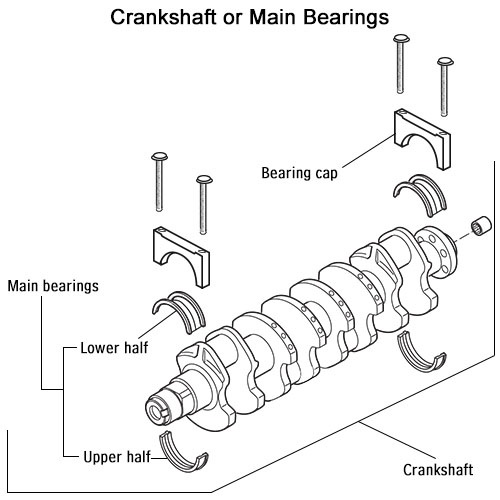

Attachment

As said before, both types of bearings are of the split-sleeve type, in which two semicircular halves, or shells, fit into each other. Of this, the upper half is in contact with the rod or crankshaft, while the lower half is in contact with a ‘bearing cap’. In case of rod bearings, the upper half is connected to the ‘big end’ of the rod, while the lower half is in contact with the rod bearing cap (below the rod), which is bolted to the rod itself. On the other hand, the upper half of a main bearing is placed in the engine block, and the lower half in the main bearing cap (above the crankshaft), which is bolted to the block itself.

Oil Supply

A ‘journal’ is the surface of a connecting rod or crankshaft which is in contact with the bearing. Since there needs to be an oil layer for lubrication between the inner surface of the bearing and the shaft, oil is supplied by an oil pump to the engine block. From here, it flows into the upper half of each main bearing. This releases the oil into the crankshaft journal (surface) by a small hole, after which the oil spreads to lubricate the entire journal. This oil then seeps into the crankshaft through minute passages, that transfer it to the rod journals (surface of crankshaft in contact with rod bearing). Thus, oil first flows into the main bearings, and then into the rod bearings.

Material Used

Being of the same split-sleeve type, both, rod and main bearings are made of similar materials. While most of the material used is steel, to impart strength, other materials like a copper-lead-tin alloy (known as ‘babbitt’), nickel, white metal, or aluminum are added to ensure that the bearing is also soft enough not to damage the shaft. However, rod bearings are smaller than main bearings in every engine.

Number of Bearings

Since each piston has one rod bearing, the total number of bearings in an engine depends on the number of cylinders. In case of main bearings, most small engines have two bearings, one at each end of the crankshaft; while others have more, one between two adjacent crankpins. Increasing the number of main bearings on a crankshaft helps it handle the flexing effect of the connecting rods better, and contributes to engine stability. However, additional main bearings need a longer crankshaft, which increases its inertia.

The above comparison indicates the importance of these bearings in engine performance. For this reason, one should keep an eye out for any symptoms of a faulty bearing, such as strange noises, poor performance, and a glowing MIL lamp.