The field of automobile technology is always in flux, with new innovations breaking the established pattern. There are few instances where old discarded ideas, find a new lease of life, leading to a technological breakthroughs. A CVT is one such old idea, that has found renewed recognition today.

What is a CVT?

You can have variable speeds of a car because of the transmission in place. Conventional transmission systems act as mediators between the engine and the driveshaft, to deliver variable torque and make speed variation possible.

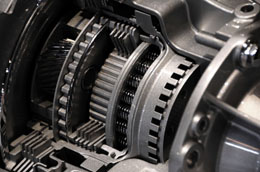

Conventional automatic transmission systems have a set of discrete gears, that come with different gear ratios, to make different drive speeds possible. A continuously variable transmission (CVT) has a continuously varying range of gears, without any discrete steps. You could say that it has infinitely many gears between the minimum and maximum gear ratios. Hence, problems with this transmission type are considerably lesser, compared to others.

This design was first conceptualized, more than 500 years ago, by none other than the polymath Leonardo da Vinci. There are many types of continuously variable transmission systems. They have been in use for long, in machines like drill presses and milling machines, as well as vehicles like tractors. Modern hybrid cars are now being built, with these transmission systems, to improve their engine efficiency.

Its Prime Parts

There are more than one ways of putting this type of transmission together. Each design has its advantages and disadvantages. Here are the three prime design types, along with information about the parts involved, in functioning of each.

Pulley Based

Compared to manual or automatic transmission systems, the design of a pulley-based CVT is simpler, with a lesser number of parts involved. The prime parts involved in such a system, are a variable diameter input pulley, an output pulley, and a V-belt that connects these two pulleys, along with several electronic devices. A change in gear ratios is achieved through the variation of distance between the pulleys and their variable diameter.

Torroidal CVT

This second type of design is similar in principle to a pulley-based CVT but still slightly different. The parts involved here are power rollers and discs, instead of pulleys and belts. There are two disks involved with two rollers in between. The gear ratios are changed through the use of an ingenious mechanism, which involves a peculiar arrangement of the disk and rollers. The rollers control the torque distribution and make infinitely many gear ratios possible, between the two extremes.

Hydrostatic CVT

These types of CVT systems use hydrostatic pumps and motors as constituent parts. The torque distribution is made possible through fluid displacement and you have a continuous range of gear ratios to choose from. Your transmission problems are substantially lowered due to the use of hydraulics and elimination of friction-prone points of contact.

Leonardo da Vinci would have been amazed to see his idea come into reality, in the form of modern continuously variable transmission systems. What intrigues you about them, is the simplicity of design. Its parts are easily available from manufacturers if you are in need of any replacements. You can order them online or visit your local car supplies store. Reliability of this transmission type is guaranteed and its design is naturally immune to the problems that beset conventional manual and automatic transmission systems. Opt for this new type of transmission and watch engine efficiency improve with time.